Garnet

Garnet

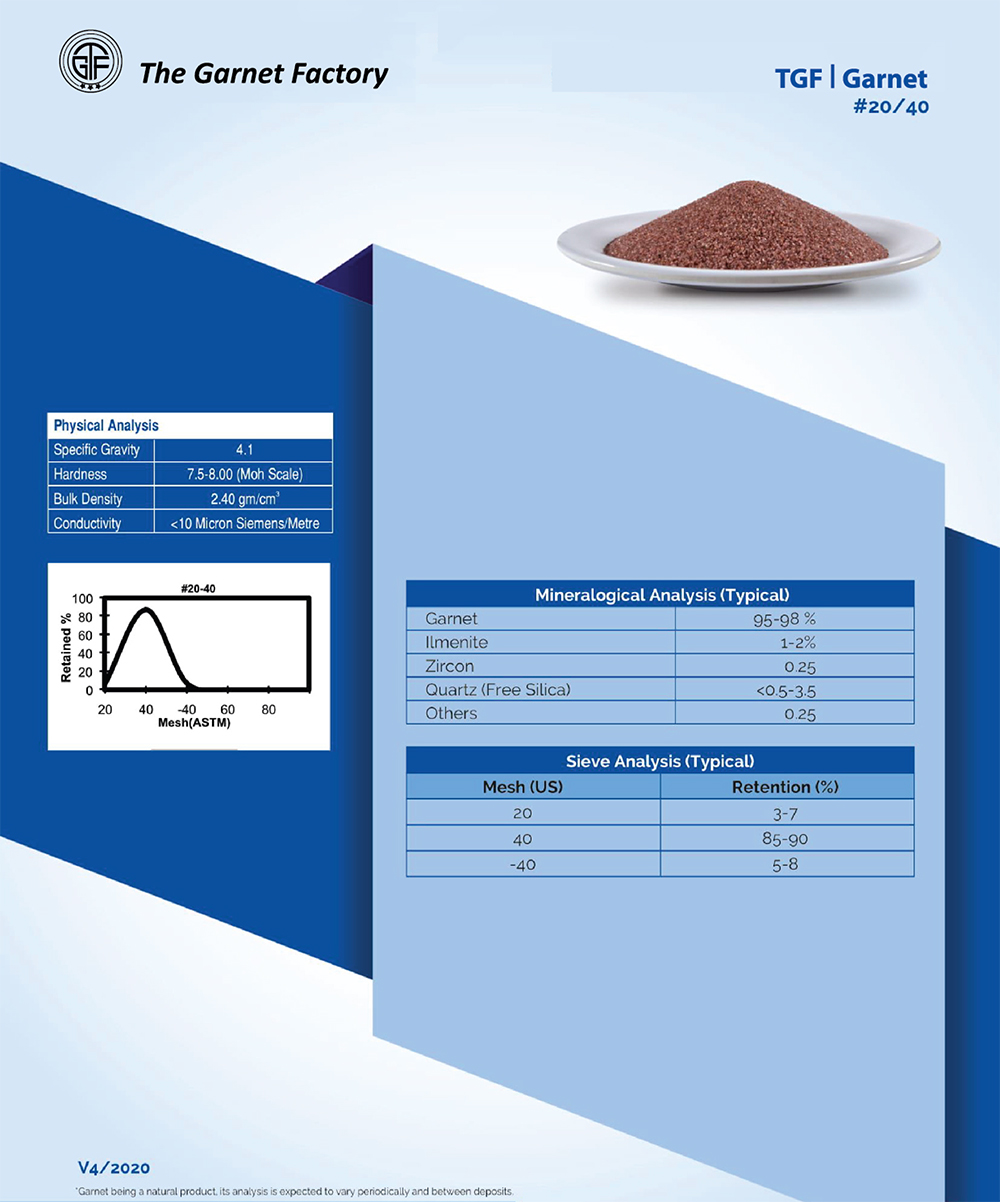

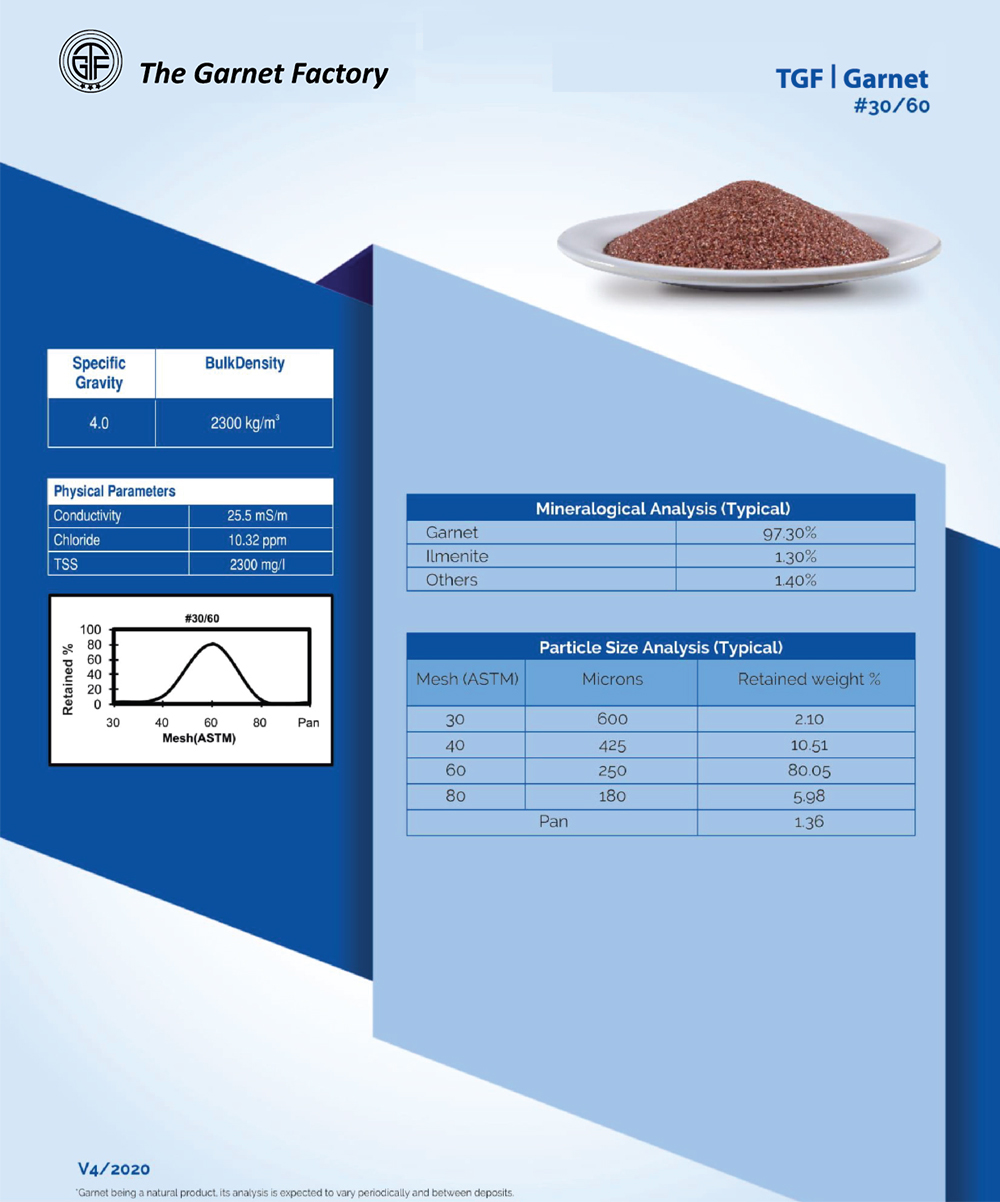

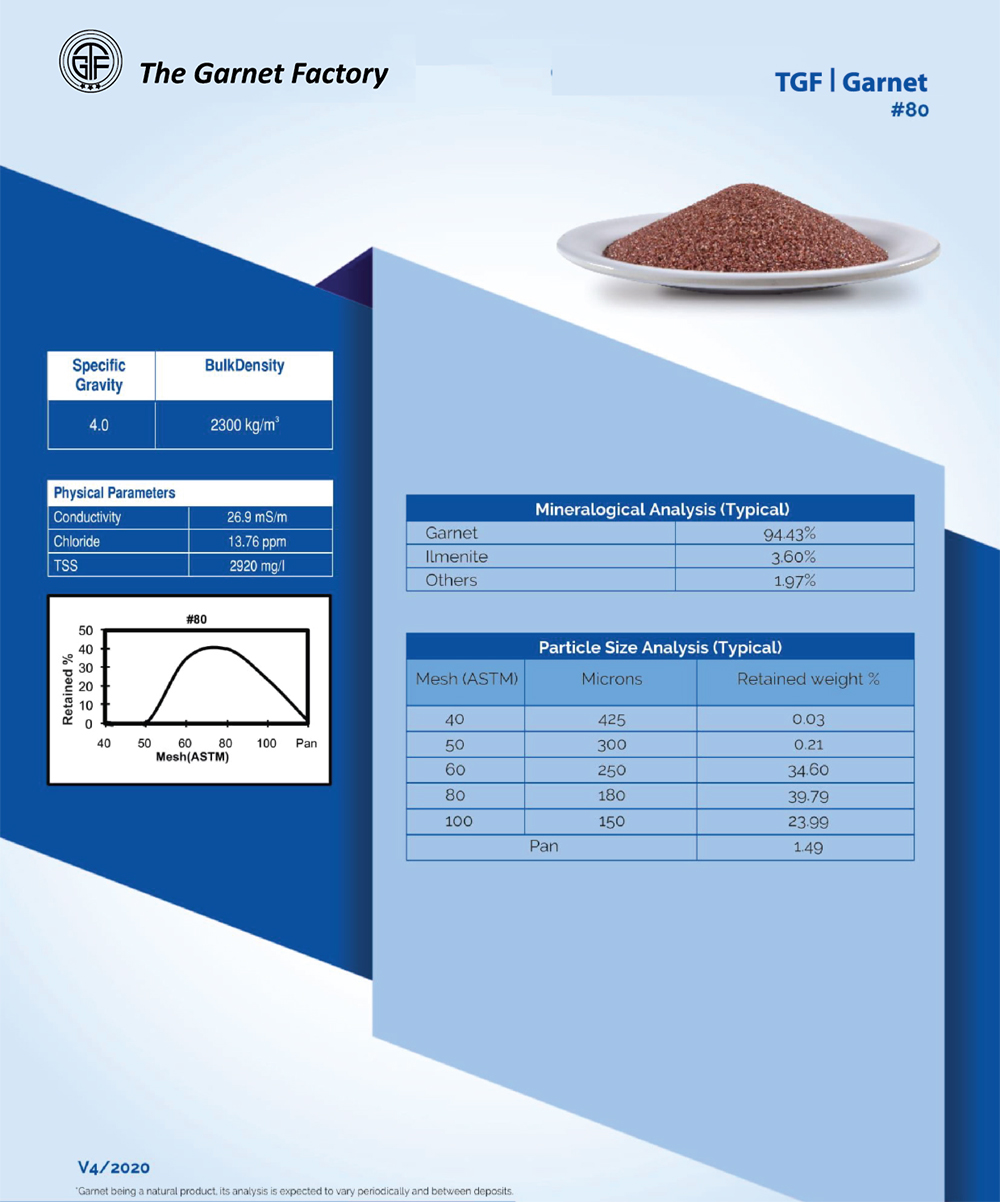

Garnet is a naturally occurring mineral and one of the most commonly used abrasives in field of surface preparation Industries. The main reason is because of its toughness, highly stability, low particle breakdown, recyclability and contain no free Silica. They are nontoxic and nonhazardous to health and environment.

Garnet sand is a mineral and iron-free product which has universal uses. Garnet abrasive sand is a naturally occurring silicate mineral deposit. The harder species of abrasive garnet like almandine are used for abrasive purposes and have hardness on the MOH scale of above 7.Once extracted; garnet sand is washed, processed, and screened to the necessary abrasive grade for use as an abrasive media.

Major areas of application are:

Abrasive Blasting is the process of forcibly propelling a stream of sand (or other abrasive material) through a nozzle against a metal surface under high pressure in order to remove completely or partially the surface contami- nants, enabling as well to roughen the surface for better coating adhesion.

Abrasive Blasting is the process of forcibly propelling a stream of sand (or other abrasive material) through a nozzle against a metal surface under high pressure in order to remove completely or partially the surface contami- nants, enabling as well to roughen the surface for better coating adhesion.

Garnet granules are also used in abrasive blasting (commonly known as "Sand Blasting"). In these processes, a tool propels a stream of abrasive granules (also known as "media") against a surface using highly pressurized fluid (usually air or water) as a propellant. Abrasive blasting is done in order to smooth, clean or remove oxidation products from metal, brick, stone and other materials.

It is a very efficient and precise cold cutting process using water jet technology. High-pressure water with abrasives cuts a wide variety of materials without

the generation of polluting heat. The cutting process is characterized by silky smooth, non-workable cutting edges and minimal kerfs. The cutting systems use

high-pressure pumps and nozzles to generate the high-pressure water jet.

It is a very efficient and precise cold cutting process using water jet technology. High-pressure water with abrasives cuts a wide variety of materials without

the generation of polluting heat. The cutting process is characterized by silky smooth, non-workable cutting edges and minimal kerfs. The cutting systems use

high-pressure pumps and nozzles to generate the high-pressure water jet.

Micro grains of TGF are perfectly suitable for the Waterjet cutting media in the Industrial purpose. Uniformity in grain size & shape give excellent performance for the users. TGF's hardness and sturdiness result in cutting-edge quality, optimum efficiency and low economics.

Garnet is found is natural state and does not require any chemical processing before it can be used. It is considered to be one of the best water filter media due to its ability of high filtration rates and longer durability. It works as an efficient support bed in backwashing filters for high-density media and used the lower filtration layer. Its high density facilitates an efficacious filter design and allows stability in the media. In addition to this, garnet sand has a high specific gravity which makes for a perfect lower layer. With its size, it can effectively filter down to the range of 10-20 micron.

Garnet has a high specific gravity. This allows for unique filter designs and lends more control during backwash resulting in lower losses hading for the drains. The angular shape provides for its superior filtration ability and makes it a convenient and ideal choice for many a water treatment applications. Its repeatability and recyclability makes it a more durable medium resulting in relatively longer production runs as com- pared to conventional water treatment medium.

Cleaning with TGF involves significantly low dust emissions due to the inher- ent toughness of the material and rapid settling due to its high specific gravity. This ensures mini- mum disruption and danger to adjoining operations and improved operator visibility & safety.

Due to large number, speed & shape of the grains impacting on the surface, TGF is very fast. Effectiveness is directly proportional to the inertia & hence the grain size. The coarser grains accelerate instantaneously & impart higher impact energy to the surface providing superior cleaning rate.

Long life, high productivity, recyclability and less wear result in immense cost saving.

TGF garnet can be recycled 3-5 times without loss in performance. Thereby, adding to efficient waste management, cost savings and environment protection. It is always recommended to add some new garnet after each use.

TGF being a totally natural product, chemically inert and free of any toxic metals or crystalline silica, assures a safe working environment and lowest possible disposal costs. There are no water-soluble constituents that contaminate water sources. It does not absorb water either and consists of dust & fine free particle mix.

TGF is natural abrasive, non-toxic free silica contents are below the allowable units. The absence of free silica eliminates silicosis hazard. There are no leaching heavy metals or radioactive contaminants that bring harm to human life.